Medical Waste Incinerators in Kenya: Containerized Solutions for Hospitals, Camps, and Donor Projects

Medical Waste Challenges in Kenya County Hospitals

Across Kenya’s healthcare system, medical waste incinerators for county hospitals are becoming increasingly essential. Growing populations in Nairobi, Kisumu, and Mombasa have led to higher volumes of hazardous waste such as syringes, infusion bags, and contaminated plastics. To comply with NEMA regulations and international donor requirements, hospitals require incinerators that guarantee high-temperature destruction, low emissions, and easy maintenance.

Containerized Incinerators for Mining and Energy Camps

Kenya’s expanding mining and energy camps in Turkana, Kitui, and coastal regions also generate large amounts of biomedical and general waste. Transporting this waste to centralized facilities is impractical and costly. For this reason, many projects are adopting containerized incinerators for Kenya mining and energy camps, which can be delivered pre-installed in 20ft or 40ft ISO containers. These mobile systems provide immediate waste destruction capacity on-site, reducing environmental risks and ensuring compliance with local and international standards.

Wet Scrubber Equipped Incinerators for Donor-Funded Projects

International organizations such as WHO, UNDP, and the World Bank often fund projects in Kenya that require strict adherence to global emission standards. In these cases, wet scrubber equipped incinerators for Kenya donor-funded projects are the preferred solution. Wet scrubbers neutralize acid gases like HCl and SO₂, minimize smoke, and protect surrounding communities from harmful pollutants. HICLOVER offers scalable emission control packages, including:

-

Basic wet scrubber systems with spray towers and ID fans.

-

Secondary washing scrubbers with cooling and defogging functions.

-

Advanced multi-stage systems with quench towers, activated carbon dosing, and baghouse filters for maximum compliance.

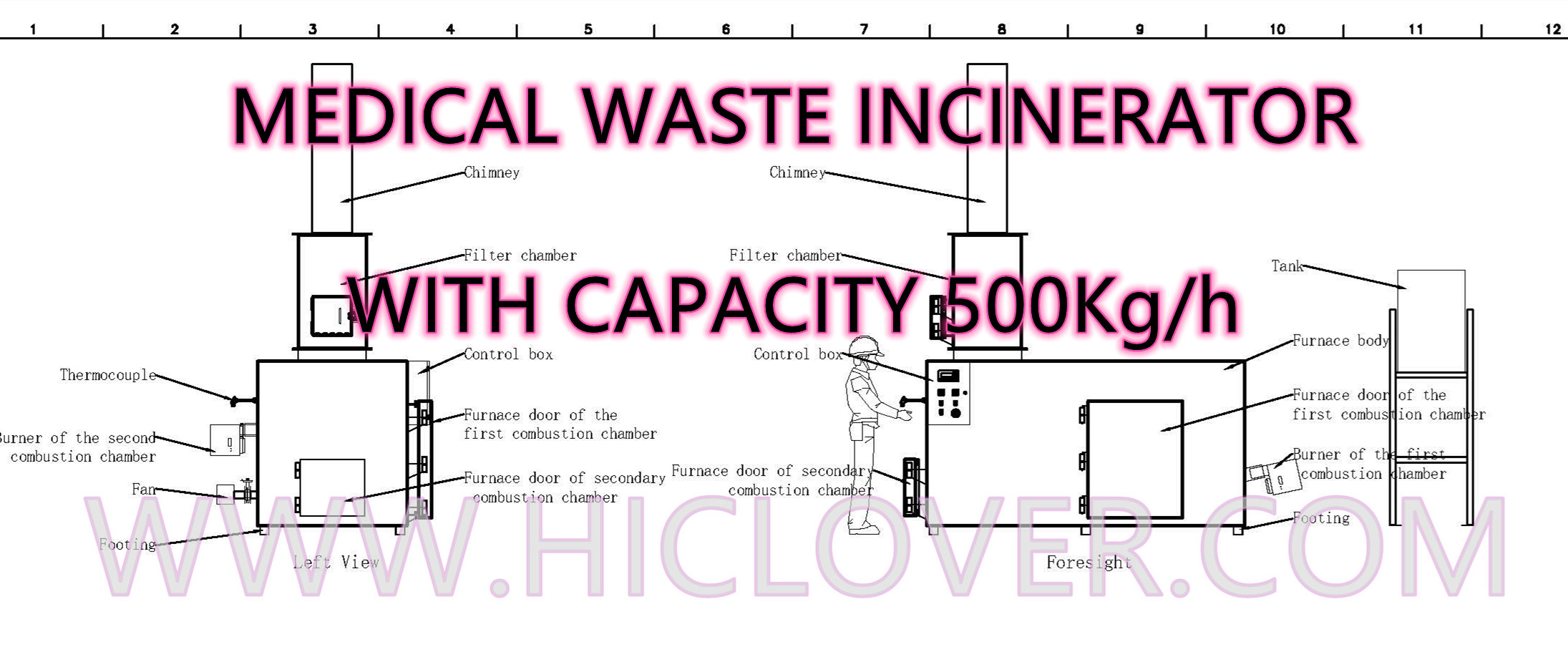

HICLOVER TS300: A Robust Choice for Kenya

The HICLOVER TS300 incinerator is designed for high-volume waste streams in hospitals and industrial camps:

-

Capacity: 250–300 kg/hour burn rate.

-

Primary Chamber: 2,800 liters with reinforced refractory lining.

-

Secondary Chamber: ≥1100°C with ≥2-second retention time.

-

PLC Automation: Fully automated ignition, burner control, and temperature monitoring with safety interlocks.

-

Containerized Deployment: Ready-to-use mobile unit for rural hospitals, mining operations, and refugee camps.

-

Optional Ash Removal System: Improves operator safety and efficiency in high-throughput environments.

Applications Across Kenya and East Africa

-

County Hospitals: On-site waste destruction ensures compliance with NEMA standards and WHO guidelines.

-

Refugee Camps: Mobile units provide reliable waste management for humanitarian operations in Kakuma and Dadaab.

-

Mining and Energy Camps: Containerized systems offer sustainable solutions for industrial projects far from urban centers.

-

Donor-Funded Clinics: Wet scrubber-equipped models meet the strictest environmental requirements for international aid projects.

Conclusion

From medical waste incinerators in Kenya county hospitals to containerized solutions for mining and energy camps, and wet scrubber-equipped incinerators for donor-funded projects, HICLOVER provides reliable, mobile, and environmentally compliant technology. With models like the TS300, Kenya’s healthcare and industrial sectors can achieve safe, sustainable, and cost-effective waste management.

For technical specifications and procurement support:

www.hiclover.com

sales@hiclover.com