Medical Waste Incineration and Medical Incinerators

The Medical range of waste incinerators from delivers highly efficient solutions

for safely disposing of all forms of hazardous, pharmaceutical, and medical waste.

Delivering the perfect solution for Hospitals, Laboratories and Aid Agencies worldwide.

machines are designed to be 40% more fuel efficient and manufactured to extremely

high standards using only the highest grade materials to give you a machine that could last you decades.

Medical incinerators are unique in their design and construction. Purpose built to

reliably destroy all of your hazardous waste efficiently and economically.

Medical waste incineration involves the burning of wastes produced by hospitals,

veterinary facilities, and medical research facilities. These wastes include both

infectious (“red bag”) medical wastes as well as non-infectious, general

housekeeping wastes. The emission factors presented here represent

emissions when both types of these wastes are combusted rather than just infectious wastes.

Three main types of incinerators are used: controlled air, excess air, and rotary kiln.

Of the incinerators identified in this study, the majority (>95 percent) are

controlled air units. A small percentage (<2 percent) are excess air.

Less than 1 percent were identified as rotary kiln.

The rotary kiln units tend to be larger, and typically are equipped

with air pollution control devices. Approximately 2 percent of the

total population identified in this study were found to be equipped with air pollution control devices.

Types of incineration described in this section include:

•Controlled air,

•Excess air, and

•Rotary kiln.

Controlled-air incineration is the most widely used medical waste incinerator (MWI)

technology, and now dominates the market for new systems at hospitals and similar

medical facilities. This technology is also known as starved-air incineration,

two-stage incineration, or modular combustion.

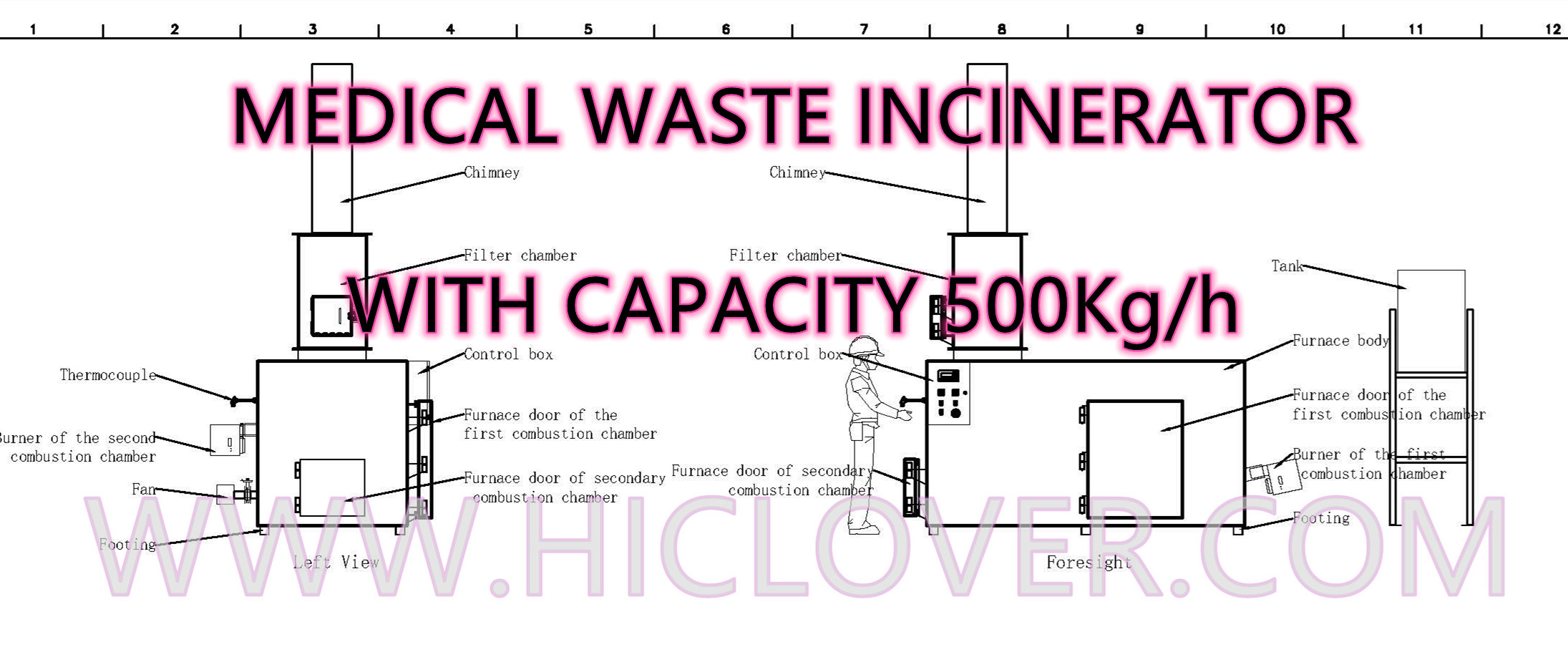

Figure 2.3-1 presents a typical schematic diagram of a controlled air unit.

Combustion of waste in controlled air incinerators occurs in two stages.

In the first stage, waste is fed into the primary, or lower, combustion

chamber, which is operated with less than the stoichiometric amount

of air required for combustion. Combustion air enters the primary

chamber from beneath the incinerator hearth (below the burning bed of waste).

This air is called primary or underfire air. In the primary (starved-air) chamber,

the low air-to-fuel ratio dries and facilitates volatilization of the waste,

and most of the residual carbon in the ash burns. At these conditions,

combustion gas temperatures are relatively low (760 to 980C [1,400 to 1,800F]).

In the second stage, excess air is added to the volatile gases formed

in the primary chamber to complete combustion. Secondary chamber

temperatures are higher than primary chamber temperatures– typically

980 to 1,095C (1,800 to 2,000F). Depending on the heating value and

moisture content of the waste, additional heat may be needed.

This can be provided by auxiliary burners located at the entrance to

the secondary (upper) chamber to maintain desired temperatures.

Waste feed capacities for controlled air incinerators range from

about 0.6 to 50 kg/min (75 to 6,500 lb/hr) (at an assumed fuel

heating value of 19,700 kJ/kg [8,500 Btu/lb]). Waste feed and

ash removal can be manual or automatic, depending on the unit

size and options purchased. Throughput capacities for lower

heating value wastes may be higher, since feed capacities are limited by primary